Speaking to some architecture students last week at Edinburgh University, I realised that two of my most recent projects occupy opposite ends of the materials spectrum: one was made from untreated steel, the other gold. From someone who started designing and making with an almost religious adherence to Birch plywood, this came as something of a shock, and it got me wondering.

The only possible reason for this divergence is that the design process, with it’s characteristic state of flux in relation to human context, has superseded my own preconceptions of what should be done. The logic of human need and the engineering of appropriate response has somehow become a liberating experience, less of a struggle, and more of a journey, with an unknown but fascinating end.

I worked in different roles for each of these projects, but both share a common logic of trying to do what I’m good at in a way that creates value. In the first project, a large joinery contractor who was refurbishing the meeting desks for the Scottish Parliament needed a way of connecting the desks securely, in a way that could be disassembled and reassembled repeatedly. The existing fittings weren’t up the to job, and the last time the desk had been stuck together with NaeNails, the silicone mastic beloved of joiners everywhere. The fittings were never seen, but had to be accurate and strong, and made within a week. These constrictions lead to a 6mm steel plate, CNC punched with holes that used replaceable bolts as location fittings. The finish was oily, the edges rough, the holes accurate in their centres to within 0.1mm, and the client was dead chuffed.

In a sense, it was the constraints of time and cost that helped resolve the design of the fittings, which anecdotally confirms the benefit of constraint. Sometimes, however, these restraints come from other, though equally compelling, directions. Safety was the major factor in the second project, where a jewellery shop sign was initially proposed in water jet cut Travertine, sandwiched between two sheets of toughened glass, and hung on the side of a building.

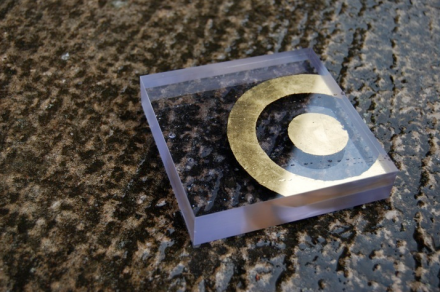

To have a chunk of stone fall on a client’s head, we all agreed, would be bad for business for everyone, not least the client, so through revision the stone became thinner, changed into stainless steel, became covered in gold leaf, and then finally BECAME gold leaf. The glass became laminated, then acrylic, and finally polycarbonate, bonded together with clear epoxy resin in a sandwich with the gold leaf in between. The project is under construction at the moment, but the sample shows that the concept of holding a precious object captive within a crystalline case has survived this transformation.

Looking at these two images, they are linked more by rigour of approach than by a formal language. I am convinced that the divergent materials are appropriate to their respective contexts, but explaining ‘what I do’ is increasingly difficult, as clients tend to focus on product, rather than process.

Is the blanket application of materials or technique by designers due to a perceived need to present a coherent catalogue of work? And could we address this poverty of ideas by allowing process to take the place of product?

Comments